Application Scenario

For a data center, a local area network (LAN), a long-haul telecommunications link, or a high-performance computing environment? Different applications have varying demands in terms of bandwidth, distance, and reliability. For example, in a data center where high-density connections and rapid data transfer between servers are crucial, a cable with specific characteristics like low latency and high fiber count might be necessary. In contrast, a LAN application might have different distance and speed requirements.

MPO|MTP fiber patch cord has become a staple for many applications. However, with a multitude of options available, making the right choice can be a challenging endeavor. Here are some essential factors to consider when selecting the ideal MPO|MTP cable for your specific requirements.

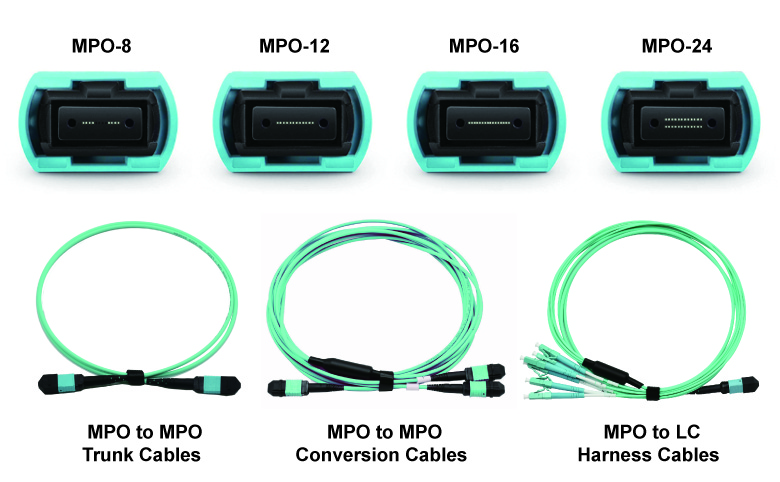

Fiber Count

MPO fiber patchcord come in a range of fiber counts. Common options include 8, 12, 16, 24 fibers. The MPO fiber count you need depends on the number of connections you have to make. If you are dealing with a small network with a limited number of devices, a lower fiber count cable might be sufficient and more cost-effective. But for large-scale deployments such as in a major data center or a metropolitan area network (MAN), a higher fiber count cable can save space and reduce installation complexity by allowing multiple connections in a single cable.

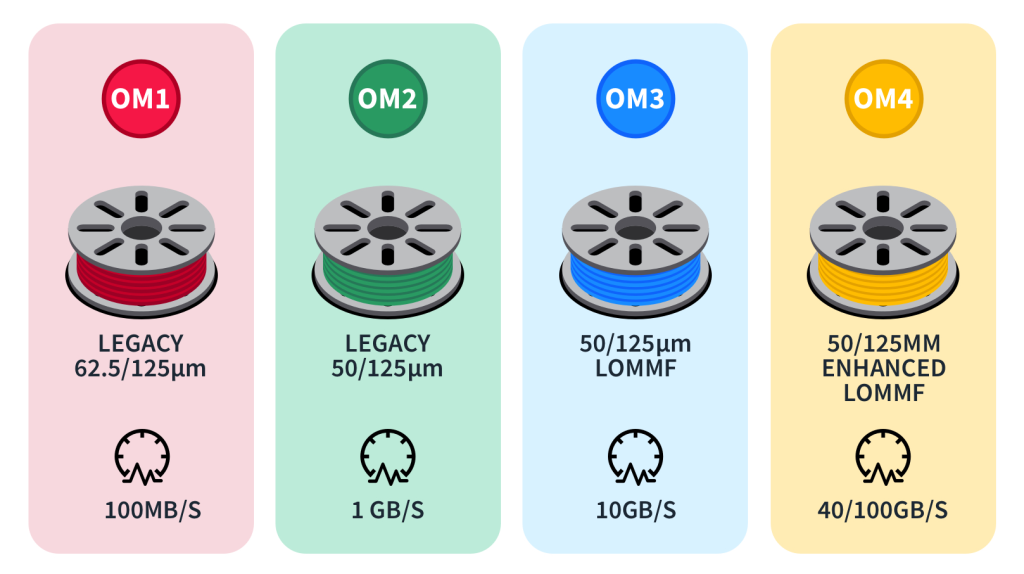

Bandwidth and Speed Requirements

Data transmission speed is crucial. MPO fiber cable is designed to support different data rates, and this is often related to the fiber type and cable construction. OM3, OM4, and OM5 are common multimode fiber types used in MPO cables. OM3 can handle 10 Gigabit per second (Gb/s) up to 300 meters, OM4 can achieve 10Gb/s up to 550 meters and 40Gb/s up to 150 meters, while OM5 is optimized for higher speeds like 40Gb/s up to 150 meters and 100Gb/s up to 100 meters. Consider your network’s current and projected future speed needs to select the appropriate fiber type within the MPO fiber patch cord.

Cable Length

Accurate measurement of the required cable length is vital. Longer fiber patchcord can experience signal attenuation, which degrades the quality of data transmission. For short connections within a rack or between adjacent racks in a data center, a cable length of a few meters might be suitable. But if you need to connect equipment across a building or over longer distances, you must calculate the exact length and choose a cable that can maintain signal integrity over that span. Some applications may also require custom cable lengths, so it’s important to work with a supplier who can accommodate such requests.

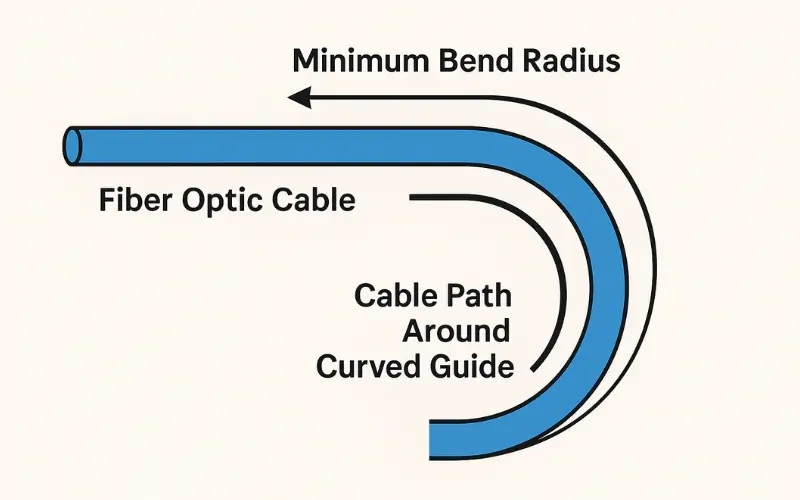

Bend Radius

In installations where MPO fiber patch cord need to be routed in tight spaces or around corners, the bend radius of the MPO fiber cable matters. A MPO fiber patch cord with a small bend radius offers more flexibility and can be installed in confined areas without compromising the signal. However, exceeding the recommended bend radius can cause micro-bending, leading to signal attenuation. Always refer to the manufacturer’s specifications for the minimum bend radius and ensure your installation adheres to these guidelines.

Connector Quality and Type

The quality of the MPO fiber connectors significantly impacts the overall performance of the cable. Look for MPO connectors with low insertion loss and high return loss to ensure minimal signal degradation during connection. There are different types of MPO connectors, such as standard MPO and MTP (a premium variant with tighter tolerances and better alignment). MTP connectors are often preferred for applications where high precision and reliability are essential. Additionally, consider the durability of the connectors, as they need to withstand repeated mating and unmating without damage.

Environmental Conditions

MPO fiber patch cord will be installed in a different indoor environment. MPO cable with special jackets that offer protection against environmental factors, such as flame-retardant. AOFPLUS offers different flame-retardant jacket, such as OFNR, OFNP or etc. PVC-OFNR is suitable for Rise area, and PVC-OFNP for Plenum area. Consider the specific environmental challenges of your installation site and choose a cable accordingly.

Cost Considerations

While it’s important not to sacrifice quality for cost, budget is always a factor. MPO patch cables with higher fiber counts, better connector quality, and advanced features like enhanced environmental protection will generally cost more. Evaluate your budget and weigh the cost against the benefits of each cable option. Sometimes, investing a bit more upfront in a higher-quality cable can save you money in the long run by reducing the need for maintenance and replacements due to performance issues.

Conclusion

Choosing the right MPO fiber optic patch cord involves a careful assessment of multiple factors. By taking into account your application scenario, fiber count, bandwidth and speed requirements, cable length, connector quality, bend radius, environmental conditions, compatibility with network equipment, and cost, you can make an informed decision that will ensure reliable and efficient fiber optic connectivity for your specific needs. Don’t rush the selection process; a well-chosen MPO cable can be the foundation for a robust and high-performing network infrastructure.